WHERE WE COME FROM

Process Vision, LLC, has been engaged in vision consulting since 2004. The OptiCount was one of the development projects undertaken by PV. It was driven by the move to sale-by-count in corn and soy, and the need to have fast and reliable count per pound information to assure that the seed counts in the package were correct. Development began in 2008 and the first patent application was submitted in 2009. With many years in the vision business, we knew that system could do much more. With growing emphasis on product variability, we saw increasing need for quantifying the size, shape and mass variability within a lot of seed.

One of the basic design concepts from the initial OptiCount development was that the product should be imaged in a uniform position so that meaningful comparisons could be made. The backlit stage is the ideal platform to achieve this objective and is a key element in the OptiCount technology. Learn more about “Settled Science” in the description of OptiCount operation.

We have been regular presenters at the Iowa State Seed Science Center’s Summer Workshops for several years, and value the opportunity to share ideas and hear feedback from the industry. Satake has featured the OptiCount at the ASTA CSS and Seed Expo for the past several years and we have begun showing the OptiCount at the ASTA Veg and Flower Seed Conference.

WHERE WE ARE

We have more than 75 OptiCount units in the field on row crops soy, corn and sunflower, on field crops wheat and canola, on a full range of flower and veg seeds. We provide count as well as dimensional and color information on seeds from the few thousand seeds per pound in corn and soy, to veg such as melon at 20K and tomato at 70K seeds per pound, to flowers like amaranth at 800K and finally to tobacco at an incredible 6 million or more seeds per pound.

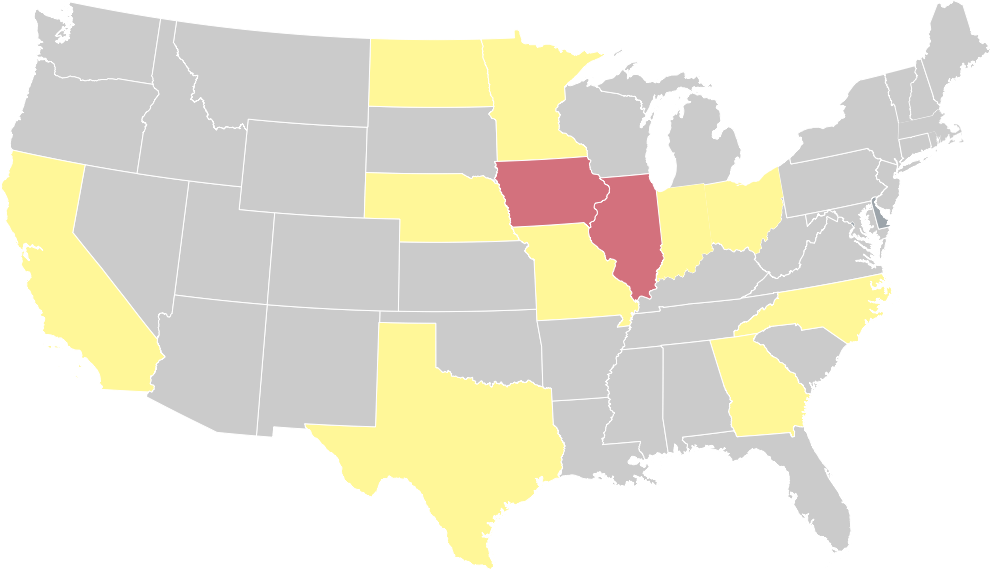

The map of OptiCount installations shows the expected concentration in the upper Midwest, but we have several units in Canada, Europe and South America. OptiCount installations are about 60% Lab and 40% OnLine, but a number of customers have an OnLine unit monitoring the process real time as well as a Lab unit doing follow-up in the QA Lab. Customers range from the largest multinationals with multiple OptiCount units in a single plant to single-line regionals with only a single OptiCount Lab.

WHERE WE ARE GOING

The OptiCount will always be a counter because that is the fastest way to get a verifiable count, but we have evolved the design from “just a counter” to a system to quantify size, shape and color variations in a wide variety of crops. As the impact of variability is better understood, the industry is recognizing the benefits of quantifying these variations in process set up, in process monitoring and in finished product documentation. We know that a complete understanding of the geometric properties of a seed lot can also contribute to better decisions in variety development and hybrid selection.

As a seed processor recently said following a demonstration of the OptiCount Lab, “Our challenge is figuring out where the industry is going to be in five years and getting there first.” Where do you want your process to be in five years?